In the context of global emphasis on energy conservation, environmental protection, and sustainable development, the construction industry is undergoing a profound transformation. As a core material that integrates fire resistance, thermal insulation, sound insulation, and structural stability, rock wool sandwich panels have become indispensable in modern architecture. Behind the widespread application of these high-performance panels lies the continuous innovation and upgrading of rock wool sandwich panel lines. These production systems have evolved from traditional manual and semi-automatic modes to highly automated, integrated production lines, fundamentally changing the efficiency and quality standards of the rock wool panel manufacturing industry.

Overview of Rock Wool Sandwich Panel Lines: Definition and Core Functions

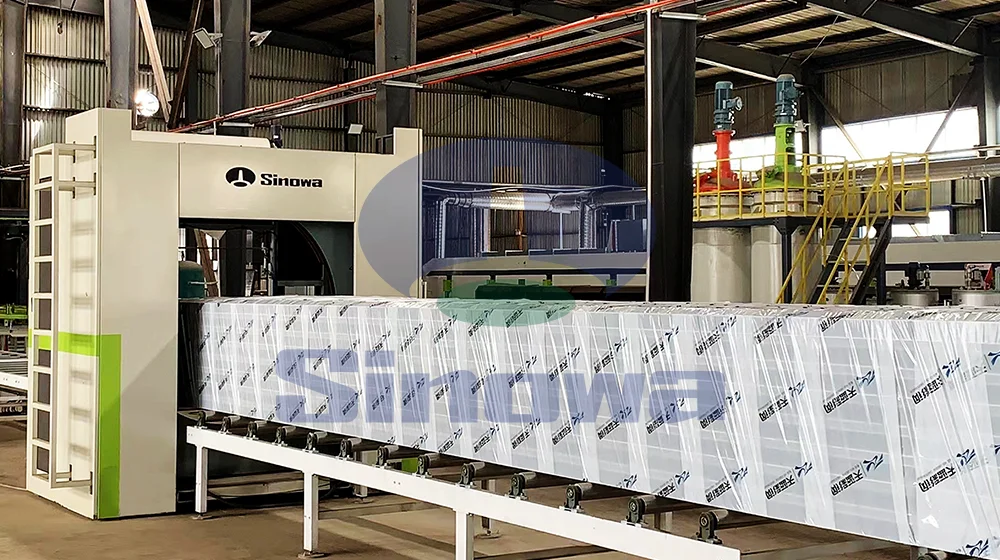

A rock wool sandwich panel line is a specialized production system designed to manufacture rock wool sandwich panels through a series of continuous processes, including raw material processing, molding, lamination, cutting, and stacking. The core product of these lines—the rock wool sandwich panel—features a typical "sandwich" composite structure, consisting of two outer metal sheets (usually galvanized steel or color-coated steel) and a middle core made of rock wool. The production line's primary function is to seamlessly integrate these three components into a unified, high-performance composite panel, ensuring the stability of the production process, the consistency of product quality, and the efficiency of mass production.

Unlike traditional discrete production methods, modern rock wool sandwich panel lines are characterized by continuity, automation, and modularization. They can achieve continuous output of panels with consistent specifications, effectively reducing manual intervention and improving production efficiency. Additionally, these lines are highly adaptable, capable of adjusting production parameters to manufacture panels of different thicknesses, sizes, and performance requirements, meeting the diverse needs of various construction scenarios. From industrial workshops and cold storage facilities to high-rise buildings and public infrastructure, the products of rock wool sandwich panel lines provide reliable material support for the construction industry.

Core Components and Working Principles of Rock Wool Sandwich Panel Lines

A complete rock wool sandwich panel line is composed of multiple functional units that work in coordination to ensure the smooth progress of the production process. Each unit has a specific role, and the rationality of its design and the accuracy of its operation directly affect the quality of the final product. The following is a detailed introduction to the core components and their working principles:

Uncoiling and Leveling System

The uncoiling and leveling system is the starting point of the production line, responsible for processing the metal coil raw materials. The metal coil (galvanized steel coil or color-coated steel coil) is placed on the uncoiler, which uncoils the coil at a stable speed. Subsequently, the uncoiled metal sheet enters the leveling machine, which eliminates the internal stress of the sheet caused by coiling and straightens the sheet. This process ensures that the metal sheet has a flat surface and uniform thickness, laying a solid foundation for subsequent molding and lamination processes. The uncoiling and leveling system is equipped with tension control devices to maintain a stable tension during the uncoiling process, preventing the metal sheet from wrinkling or deviating.

Roll Forming System

The roll forming system is responsible for shaping the leveled metal sheet into the required cross-sectional shape. According to the design requirements of the rock wool sandwich panel (such as corrugated, V-shaped, or hidden connection type), the roll forming machine uses a series of sequentially arranged forming rollers to gradually bend the metal sheet into the desired shape. The forming process is carried out continuously and at a constant speed, ensuring the consistency of the shape and size of the metal panel. The roll forming system is characterized by high forming accuracy, fast speed, and strong adaptability, and can be adjusted according to different panel specifications to achieve rapid product switching.

Rock Wool Feeding and Cutting System

The rock wool feeding and cutting system is responsible for processing the rock wool core material. The rock wool, which is usually supplied in the form of large rolls or blocks, is transported to the feeding device through a conveyor belt. The feeding device adjusts the feeding speed according to the production speed of the main line to ensure a continuous and stable supply of rock wool. Subsequently, the rock wool is cut into pieces of the required length by a cutting machine. The cutting accuracy directly affects the fit between the rock wool core and the metal panel. Modern rock wool cutting systems adopt high-precision cutting tools and automatic control technology, which can achieve precise cutting of rock wool with different thicknesses (usually 30mm to 120mm) and ensure the flatness of the cutting surface.

Adhesive Coating System

The adhesive coating system is a key part of ensuring the bonding strength between the metal panel and the rock wool core. The system uniformly applies high-performance adhesive (usually polyurethane or modified phenolic resin) to the inner surface of the formed metal panel. The adhesive plays the role of a "connecting bridge", firmly bonding the metal panel and the rock wool core into an integrated structure. The coating amount and uniformity of the adhesive are crucial to the bonding effect. Too little adhesive will lead to insufficient bonding strength and easy delamination; too much adhesive will increase production costs and may affect the performance of the panel. Modern adhesive coating systems adopt automatic coating devices with adjustable coating amount, which can ensure uniform coating of the adhesive on the metal panel surface and improve the bonding quality.

Lamination and Compression System

The lamination and compression system is responsible for combining the upper metal panel, rock wool core, and lower metal panel into a composite structure. After the adhesive is coated, the upper and lower metal panels and the rock wool core are transported to the lamination machine at the same time. Under the action of the lamination roller, the three components are tightly pressed together. The compression pressure and speed are precisely controlled to ensure that the adhesive is fully bonded and the internal air of the composite structure is discharged. This process enables the metal panels and rock wool core to work synergistically, forming a composite panel with high bending stiffness and bearing capacity. The lamination and compression system also plays a role in shaping the composite panel, ensuring the flatness and dimensional accuracy of the panel surface.

Cutting and Cooling System

After lamination and compression, the continuous composite panel enters the cutting and cooling system. The cutting machine cuts the continuous panel into finished products of the required length according to the customer's order requirements. The cutting process adopts high-speed cutting tools, which can achieve fast and precise cutting without damaging the panel structure. The cooling system cools the cut finished products to room temperature. Since the adhesive may generate heat during the curing process, cooling can accelerate the curing of the adhesive and ensure the stability of the product performance. The cooled finished products are then transported to the stacking system.

Stacking and Packaging System

The stacking and packaging system is the end of the production line. The stacking machine automatically stacks the cooled finished products in an orderly manner according to the specified quantity and specifications. The stacking process is carried out automatically, which reduces manual labor and improves stacking efficiency. After stacking, the finished products are packaged with packaging materials (such as plastic film or cartons) to prevent damage during transportation and storage. The packaging system can also be equipped with labeling devices to print product information (such as specifications, production date) on the packaging, facilitating product management and traceability.

Control System

The control system is the "brain" of the entire rock wool sandwich panel line, responsible for coordinating the operation of all functional units. Modern rock wool sandwich panel lines adopt PLC (Programmable Logic Controller) programmable control systems, which can realize automatic control of the production process. The control system is equipped with a touch screen operation interface, through which operators can set production parameters (such as production speed, panel thickness, cutting length), monitor the operation status of the production line, and handle faults in a timely manner. Some advanced control systems also have remote monitoring and diagnosis functions, which can realize remote monitoring of the production line and timely maintenance, improving the reliability and stability of the production line operation.

Performance Advantages of Modern Rock Wool Sandwich Panel Lines

Compared with traditional production methods, modern rock wool sandwich panel lines have significant performance advantages in terms of production efficiency, product quality, energy conservation and environmental protection, and operational flexibility. These advantages have made them the mainstream production equipment in the rock wool sandwich panel industry.

High Production Efficiency

Modern rock wool sandwich panel lines adopt continuous production modes, which can achieve high-speed and continuous output of products. The production speed can reach 4-16 meters per minute on average, and the annual output can reach about 800,000 square meters, which is far higher than that of traditional manual and semi-automatic production methods. The high degree of automation of the production line reduces manual intervention, shortens the production cycle, and improves the utilization rate of equipment. In addition, the modular design of the production line enables rapid switching of product specifications, adapting to the needs of small-batch and multi-variety production, and further improving production efficiency.

Stable Product Quality

The automatic control system of modern rock wool sandwich panel lines can precisely control various production parameters (such as forming pressure, adhesive coating amount, cutting length), ensuring the consistency of product quality. The use of high-precision equipment (such as roll forming machines, cutting machines) improves the dimensional accuracy and surface flatness of the products. At the same time, the production line reduces the impact of human factors on product quality, avoiding quality problems such as uneven bonding, inaccurate cutting, and surface defects caused by manual operation. The stable product quality ensures that the rock wool sandwich panels have reliable performance in terms of fire resistance, thermal insulation, and structural stability, meeting the strict requirements of the construction industry.

Energy Conservation and Environmental Protection

With the increasing emphasis on environmental protection, modern rock wool sandwich panel lines have adopted a series of energy-saving and environmental protection technologies. In terms of energy consumption, the power configuration of the production line is optimized, and energy-saving motors and frequency conversion control technologies are used to reduce energy consumption during operation. The average power consumption of a typical production line is about 200kW, which is significantly lower than that of traditional production equipment. In terms of environmental protection, the production line is equipped with dust removal and waste gas treatment devices to reduce the emission of dust and harmful gases during the production process. In addition, the rock wool core material used in the production process is an inorganic mineral material, which is non-combustible and does not produce toxic gases when burned, and can be recycled, in line with the concept of green and sustainable development.

High Operational Flexibility

Modern rock wool sandwich panel lines adopt modular design, and each functional unit can be flexibly combined and configured according to production needs. The production line can not only produce rock wool sandwich panels but also produce composite panels with other core materials (such as polyurethane, glass wool) by replacing core material feeding devices. At the same time, the production line can adjust production parameters to produce panels of different specifications (such as different thicknesses, lengths, widths) and different types (such as roof panels, wall panels, cold storage panels), meeting the diverse needs of different construction projects. The high operational flexibility of the production line improves the adaptability of enterprises to the market and enhances their core competitiveness.

Application Scenarios of Products from Rock Wool Sandwich Panel Lines

The rock wool sandwich panels produced by rock wool sandwich panel lines have excellent comprehensive performance, making them widely used in various fields of the construction industry. From industrial buildings to civil buildings, from indoor decoration to outdoor enclosure, these panels play an important role in improving the safety, comfort, and energy efficiency of buildings.

Industrial Buildings

Industrial workshops, factories, and warehouses have high requirements for the fire resistance, thermal insulation, and sound insulation of building materials. Rock wool sandwich panels are ideal enclosure materials for these buildings. The panels have excellent fire resistance, which can effectively prevent the spread of fire and protect the safety of personnel and property. At the same time, the good thermal insulation performance of the panels can reduce the energy consumption of industrial production, improving the energy efficiency of the workshop. In addition, the sound insulation performance of the panels can reduce the noise generated by production equipment, improving the working environment of employees. Rock wool sandwich panels are also lightweight and high-strength, which can reduce the load of the building structure and shorten the construction cycle.

Civil Buildings

In civil buildings such as residential buildings, office buildings, and shopping malls, rock wool sandwich panels are widely used in exterior walls, roofs, and interior partitions. The exterior wall panels made of rock wool sandwich panels have good thermal insulation and thermal insulation performance, which can reduce the energy consumption of heating and air conditioning in buildings, meeting the requirements of building energy conservation. The roof panels have excellent waterproof and wind resistance performance, which can ensure the tightness of the building roof and prevent leakage. The interior partition panels have good sound insulation performance, which can improve the privacy and comfort of the indoor space. In addition, the color-coated metal surface of the rock wool sandwich panel has a variety of colors and styles, which can meet the aesthetic requirements of different buildings.

Cold Storage and Refrigeration Facilities

Cold storage and refrigeration facilities have strict requirements for the thermal insulation performance of building materials. The rock wool sandwich panels produced by rock wool sandwich panel lines have low thermal conductivity and excellent thermal insulation performance, which can effectively reduce the heat exchange between the inside and outside of the cold storage, maintaining a stable low-temperature environment inside the cold storage. At the same time, the panels have good moisture resistance, which can prevent moisture from entering the cold storage and affecting the quality of stored goods. The lightweight and high-strength characteristics of the panels also facilitate the construction and expansion of cold storage facilities.

Public Infrastructure

In public infrastructure such as airports, railway stations, and subway stations, rock wool sandwich panels are widely used in enclosure structures and interior decoration. These places have large passenger flow and high requirements for fire safety and sound insulation. The excellent fire resistance of rock wool sandwich panels can ensure the safety of personnel evacuation in case of fire. The good sound insulation performance can reduce the noise in public places, improving the comfort of passengers. In addition, the panels have good durability and can withstand the erosion of the external environment, ensuring the long-term stable operation of public infrastructure.

Development Trends of Rock Wool Sandwich Panel Lines

With the continuous advancement of the global construction industry towards greenization, intelligence, and modularization, rock wool sandwich panel lines are also facing new development opportunities and challenges. In the future, the development of these lines will focus on intelligence upgrading, green production, technological innovation, and industrial integration, constantly improving production efficiency and product quality, and promoting the high-quality development of the rock wool sandwich panel industry.

Intelligence Upgrading

Intelligence will be the core direction of the future development of rock wool sandwich panel lines. With the wide application of technologies such as the Internet of Things, big data, and artificial intelligence, future production lines will realize full-process intelligent monitoring and control. Sensors installed on the production line will collect real-time data on various production parameters (such as temperature, pressure, speed), and the big data analysis system will analyze and process these data to optimize production parameters and improve production efficiency. The artificial intelligence system can predict potential faults of the production line and send early warning signals, realizing predictive maintenance of the production line. In addition, the integration of the production line with the enterprise's information management system will realize the seamless connection between production, sales, and inventory, improving the overall operation efficiency of the enterprise.

Green Production

Under the background of global carbon neutrality goals, green production will become an important requirement for rock wool sandwich panel lines. In the future, production lines will further optimize energy consumption structures, adopt more efficient energy-saving technologies, and reduce carbon emissions during production. At the same time, the production line will strengthen the recycling and utilization of waste materials, such as recycling and reprocessing waste rock wool and metal scraps, reducing resource waste. In addition, the development of environmentally friendly adhesives and other raw materials will further improve the environmental performance of products, meeting the increasingly strict environmental protection requirements of various countries.

Technological Innovation

Technological innovation will be the driving force for the development of rock wool sandwich panel lines. In terms of equipment technology, the future production line will adopt more advanced forming, lamination, and cutting technologies to improve the precision and efficiency of the production process. For example, the application of laser cutting technology will further improve the cutting accuracy and speed of panels. In terms of material technology, the development of high-performance rock wool core materials and adhesives will improve the fire resistance, thermal insulation, and durability of products. In addition, the research and development of new product structures (such as composite panels with multi-layer core materials) will expand the application fields of products. The continuous innovation of production line technology will help enterprises improve their core competitiveness and occupy a favorable position in the market competition.

Industrial Integration

The future development of rock wool sandwich panel lines will tend to integrate with upstream and downstream industries. On the one hand, the production line will strengthen the connection with raw material suppliers (such as metal coil and rock wool manufacturers) to ensure the stable supply and quality of raw materials. On the other hand, the production line will integrate with downstream construction and decoration industries, realizing the customization of products according to the needs of construction projects. The development of modular construction will also promote the integration of rock wool sandwich panel lines with the prefabricated building industry. The production line will produce standardized and modular rock wool sandwich panels, which can be directly assembled on the construction site, shortening the construction cycle and improving the construction quality. The integration of industries will promote the coordinated development of the entire industrial chain, forming a mutually beneficial and win-win industrial ecosystem.

Conclusion

As an important part of the modern construction material production industry, rock wool sandwich panel lines have undergone tremendous changes from traditional manual production to modern intelligent production. These lines not only improve the production efficiency and product quality of rock wool sandwich panels but also promote the green and sustainable development of the construction industry through energy conservation and environmental protection technologies. The products of rock wool sandwich panel lines are widely used in various fields of the construction industry, providing reliable material support for improving the safety, comfort, and energy efficiency of buildings.

Looking to the future, with the continuous advancement of intelligence, greenization, and technological innovation, rock wool sandwich panel lines will usher in a new development stage. The intelligent upgrading of production lines will realize full-process intelligent monitoring and control, improving production efficiency and operational reliability; green production will help enterprises achieve carbon emission reduction goals and meet environmental protection requirements; technological innovation will promote the continuous improvement of product performance and the expansion of application fields; industrial integration will promote the coordinated development of the entire industrial chain and enhance the overall competitiveness of the industry. It is believed that in the future, rock wool sandwich panel lines will play a more important role in the global construction industry, making greater contributions to the construction of a sustainable and low-carbon society.

« Rock Wool Sandwich Panel Line » Update Date: 2026/1/9

URL: https://www.sinowamachine.com/tags/rock-wool-sandwich-panel-line.html