In the context of global emphasis on energy conservation, environmental protection and building safety, rock wool sandwich panels have emerged as a pivotal building material in industrial construction, public facilities and logistics warehousing. As the cradle of these high-performance panels, rock wool sandwich panel manufacturing plants play a decisive role in ensuring product quality, optimizing production efficiency and promoting industry upgrading.

Overview of Rock Wool Sandwich Panels and Manufacturing Plant Significance

Rock wool sandwich panels are composite materials composed of two outer metal sheets and a middle rock wool core. The unique structure endows them with multiple superior properties, including excellent fire resistance, thermal insulation, sound absorption, and mechanical strength. Unlike traditional single-function building materials, rock wool sandwich panels integrate multiple functions into one, which can significantly shorten the construction period, reduce overall building costs, and enhance the safety and comfort of buildings. These advantages make them widely used in industrial workshops, cold storage centers, data centers, prefabricated buildings and other fields.

The manufacturing plant is the key link in the industrial chain of rock wool sandwich panels. It is not only responsible for transforming raw materials into finished products that meet market demand but also bears the responsibility of promoting technological innovation and industrial upgrading. A well-equipped and scientifically managed manufacturing plant can ensure the stability and consistency of product performance, while optimizing production processes to reduce resource consumption and environmental impact. With the continuous improvement of global building standards and the increasing demand for green buildings, the role of rock wool sandwich panel manufacturing plants in promoting the sustainable development of the construction industry has become increasingly prominent.

Raw Material Selection: The Foundation of High-Quality Products

The quality of rock wool sandwich panels largely depends on the selection of raw materials. Rock wool sandwich panel manufacturing plants adhere to strict standards in raw material procurement and inspection to ensure that each component meets the requirements of subsequent production processes and product performance. The raw materials mainly include rock wool core materials, metal surface materials and adhesives, each of which has specific selection criteria.

Rock Wool Core Material

As the core component of the sandwich panel, the rock wool core material directly determines the thermal insulation, fire resistance and sound absorption performance of the product. High-quality rock wool core materials are usually made of natural basalt as the main raw material, supplemented by other auxiliary materials such as dolomite. Basalt is selected for its abundant reserves, high melting point and stable chemical properties, which can ensure the excellent fire resistance of the rock wool core material. During the selection process, the manufacturing plant will focus on testing the key indicators of the rock wool core material, such as density, fiber diameter, slag ball content and thermal conductivity. Generally, the density of the rock wool core material for sandwich panels is between 100-150 kg/m³, the fiber diameter is less than 7 μm, and the thermal conductivity is as low as 0.036-0.042 W/(m·K), which can effectively block heat transfer and achieve good energy-saving effects.

Metal Surface Material

The outer metal sheets of rock wool sandwich panels play a role in protecting the core material and bearing external loads. Common metal surface materials include galvanized steel sheets, color-coated steel sheets and aluminum-zinc alloy sheets. These materials are selected for their good corrosion resistance, mechanical strength and weather resistance. When selecting, the manufacturing plant will pay attention to the thickness of the metal sheet, the adhesion of the coating and the flatness of the surface. The thickness of the metal sheet is usually between 0.4-0.8 mm, which can balance the structural strength and product weight. The coating of color-coated steel sheets needs to have strong adhesion and resistance to ultraviolet radiation, to ensure that the panel surface does not fade or peel under long-term outdoor exposure. In addition, the metal sheet must undergo strict flatness inspection to avoid affecting the bonding effect with the core material and the overall appearance of the finished product.

Adhesive

The adhesive is the key to ensuring the bonding strength between the rock wool core material and the metal surface material. High-performance adhesives need to have strong bonding force, good high-temperature resistance and environmental friendliness. Common adhesives used in rock wool sandwich panels include polyurethane adhesives and epoxy resin adhesives. When selecting adhesives, the manufacturing plant will test their bonding strength, curing time and volatile organic compound (VOC) content. The bonding strength between the core material and the metal sheet should be greater than 0.12 MPa to prevent delamination during use. At the same time, the adhesive must meet environmental protection requirements, with low VOC emissions, to avoid polluting the environment and endangering human health.

Before entering the production line, all raw materials must go through strict incoming inspection. The manufacturing plant will set up a special quality inspection department to sample and test each batch of raw materials. Only the raw materials that pass the inspection can be put into production, which lays a solid foundation for the production of high-quality rock wool sandwich panels.

Core Production Processes: From Raw Materials to Finished Products

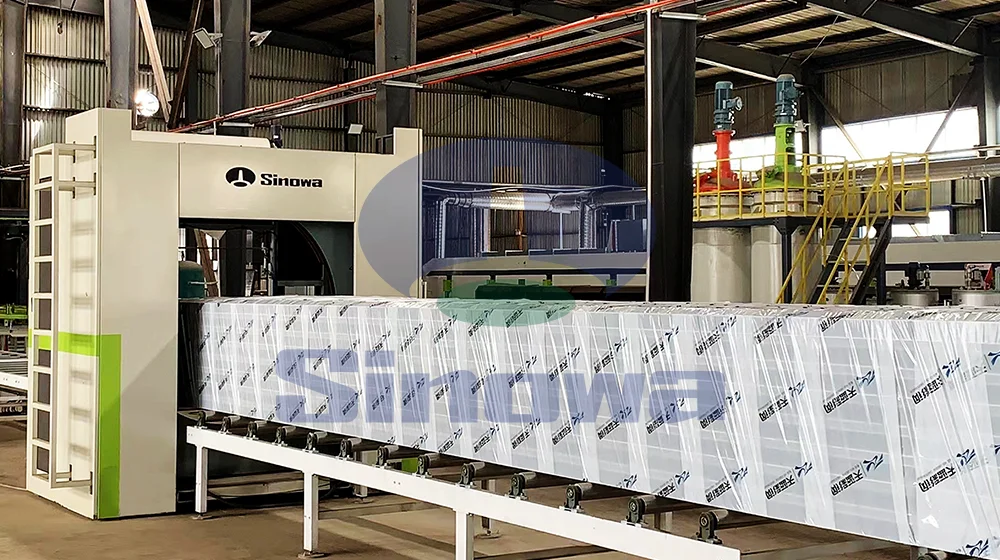

The production process of rock wool sandwich panels in the manufacturing plant is a highly automated and systematic process, which mainly includes raw material pretreatment, rock wool core material preparation, composite bonding, forming and cutting, and other key links. Each link has strict process parameters and operation standards to ensure the stability and consistency of product quality.

Raw Material Pretreatment

Raw material pretreatment includes the pretreatment of metal sheets and the preparation of rock wool core materials. For metal sheets, the main processes are uncoiling, cleaning and leveling. First, the coiled metal sheet is smoothly uncoiled by an uncoiler, and the tension during uncoiling is precisely controlled to avoid scratches on the surface of the metal sheet. Then, the uncoiled metal sheet enters the cleaning equipment to remove oil stains, dust and other impurities on the surface, which ensures the bonding effect between the metal sheet and the adhesive. Finally, the cleaned metal sheet is leveled by a multi-roll leveler to ensure that the flatness error is controlled within 0.5 mm/m, providing a flat base for subsequent composite processes. After pretreatment, the metal sheet is cut into a specific width by a CNC shearing machine according to the order requirements, and the cutting accuracy is controlled within ±0.3 mm.

The preparation of the rock wool core material is carried out simultaneously with the pretreatment of the metal sheet. First, the selected basalt and other raw materials are put into a melting furnace and heated to a high temperature of 1400-1600 °C to melt them into a molten state. Then, the molten rock is sprayed into fibers by a centrifugal spinneret, and a small amount of binder is added during the spraying process. The fibers are then evenly scattered and piled up by a high-speed air flow, and formed into a rock wool blanket with a three-dimensional structure through a pendulum process. Finally, the rock wool blanket is pressed and solidified to form a rock wool board with a specified density. The rock wool board is cut into core materials of different thicknesses (30 mm-150 mm) by high-precision CNC cutting equipment according to the product requirements. A dust removal system is installed during the cutting process to avoid the spread of rock wool fibers and ensure the cleanliness of the production environment.

Composite Bonding

Composite bonding is the core link in the production of rock wool sandwich panels, which directly affects the bonding strength and overall performance of the product. First, the pretreated metal sheets are sent to the adhesive coating station, and the high-performance adhesive is evenly coated on the inner surface of the metal sheet by a precision coating machine. The coating amount is precisely controlled between 200-300 g/m² to ensure sufficient bonding force while avoiding waste of adhesive. Then, the cut rock wool core material is accurately stacked between the upper and lower metal sheets through a precision alignment system. The aligned composite material enters a double-track continuous composite machine, and under the conditions of a specified temperature (160-180 °C) and pressure (0.3-0.5 MPa), it is subjected to continuous heating and pressure for 6-8 minutes to fully cure the adhesive and form a firm composite structure. The composite machine is equipped with an imported temperature control system and a pressure sensor to real-time monitor the temperature and pressure during the composite process, ensuring uniform temperature on each part of the panel surface and stable pressure, thus avoiding bonding defects caused by temperature and pressure differences.

Forming and Cutting

After composite bonding, the panel enters the forming process. According to the different requirements of the application scenario, the flat panel is processed into various shapes (such as hidden buckle type, tongue-and-groove type) by a precision roll forming machine. During the forming process, the mold temperature is controlled between 60-80 °C, which not only ensures the forming accuracy but also avoids damage to the metal sheet coating. The formed panel enters the cooling section to be uniformly cooled to below 40 °C to ensure the stability of the panel structure. Then, the cooled panel is sent to the fixed-length cutting station, and the panel is cut into finished products of specified lengths by a servo-controlled flying saw cutting system. The cutting accuracy is as high as ±1 mm, and the cut is flat without burrs. Finally, the cut finished products are neatly stacked by an automatic stacking device to avoid edge damage during transportation.

Quality Control System: Full-Process Assurance of Product Reliability

Rock wool sandwich panel manufacturing plants establish a comprehensive quality control system covering the entire production process from raw material incoming inspection to finished product delivery, to ensure that each batch of products meets the quality requirements. The quality control system includes strict inspection standards, advanced testing equipment and professional quality inspection personnel.

In-Process Quality Inspection

In-process quality inspection runs through every link of production. During the raw material pretreatment stage, the quality inspection personnel will check the flatness, cleanliness and cutting accuracy of the metal sheet, as well as the density, fiber structure and cutting size of the rock wool core material. During the composite bonding stage, the coating amount of the adhesive, the alignment accuracy of the core material and the metal sheet, and the temperature and pressure parameters of the composite machine are monitored in real time. If any parameter is found to be abnormal, the production line will be stopped immediately for adjustment. During the forming and cutting stage, the shape, size and surface quality of the panel are inspected to ensure that the forming accuracy meets the requirements and the surface is free of scratches, dents and other defects.

Finished Product Inspection

Finished product inspection is the final guarantee of product quality. The inspection items mainly include appearance quality, dimensional accuracy, physical properties and functional performance. In terms of appearance quality, the quality inspection personnel check the flatness of the panel surface, the integrity of the coating, the uniformity of color and the tightness of the joints. In terms of dimensional accuracy, the length, width, thickness and diagonal deviation of the panel are measured with professional measuring tools. In terms of physical properties, the bonding strength, compressive strength and bending capacity of the panel are tested with a universal testing machine. In terms of functional performance, key indicators such as thermal conductivity, fire resistance and sound absorption performance are tested. For example, the thermal conductivity of the panel is measured by a thermal conductivity tester, and the fire resistance is tested by simulating high-temperature environments. Only the finished products that pass all inspection items can be put into storage and sold.

Quality Traceability System

To further ensure product quality, rock wool sandwich panel manufacturing plants also establish a quality traceability system. Each batch of products is assigned a unique batch number, which is marked on the product packaging. The batch number is associated with information such as raw material suppliers, production time, production personnel and inspection results. If quality problems occur in the product during use, the manufacturer can quickly trace the relevant production links through the batch number, find out the cause of the problem and take corresponding corrective measures. The quality traceability system not only improves the accountability mechanism of the production process but also provides a reliable guarantee for after-sales service.

Environmental Protection Measures: Green Production in Response to Global Environmental Requirements

With the increasing global emphasis on environmental protection, rock wool sandwich panel manufacturing plants have actively taken a series of environmental protection measures to achieve green production, reduce environmental impact and respond to the call for sustainable development.

Waste Gas and Dust Treatment

During the production process, especially in the rock wool core material preparation stage, a small amount of waste gas and dust will be generated. The manufacturing plant installs professional waste gas treatment equipment and dust removal systems to purify the waste gas and dust. For example, the dust generated during the rock wool cutting process is collected by a bag-type dust remover, and the dust removal efficiency reaches more than 99%. The waste gas generated during the melting of raw materials is treated by a desulfurization and denitrification system to reduce the emission of harmful gases such as sulfur dioxide and nitrogen oxides. After treatment, the waste gas and dust meet the national emission standards before being discharged.

Waste Water Treatment and Recycling

The waste water generated in the production process mainly comes from the cleaning of metal sheets. The manufacturing plant builds a waste water treatment station to treat the waste water. The waste water is treated through processes such as sedimentation, filtration and neutralization to remove oil stains, suspended solids and other impurities in the water. The treated waste water can reach the reuse standard and be reused in the metal sheet cleaning process, realizing the recycling of water resources and reducing water consumption.

Waste Resource Utilization

The manufacturing plant also pays attention to the utilization of waste resources. The leftover materials generated during the production process (such as leftover metal sheets and rock wool scraps) are classified and recycled. The leftover metal sheets are sent to professional recycling agencies for reprocessing and reuse. The rock wool scraps can be reprocessed into rock wool core materials, realizing the recycling of resources. In addition, the manufacturing plant also optimizes the production process to reduce the generation of waste. For example, by improving the cutting accuracy of the CNC cutting equipment, the amount of leftover materials is reduced.

Energy Conservation and Emission Reduction

To reduce energy consumption, rock wool sandwich panel manufacturing plants actively adopt energy-saving equipment and technologies. For example, the melting furnace uses high-efficiency energy-saving burners to improve fuel utilization efficiency and reduce energy consumption. The production line is equipped with frequency conversion speed regulation systems to adjust the operation speed of the equipment according to the production load, avoiding unnecessary energy waste. At the same time, the manufacturing plant strengthens the management of energy consumption, establishes an energy consumption statistics system, and regularly analyzes and optimizes energy consumption indicators to achieve the goal of energy conservation and emission reduction.

Application Scenarios and Market Demand of Rock Wool Sandwich Panels

The excellent performance of rock wool sandwich panels makes them have a wide range of application scenarios, and the market demand is constantly expanding, which provides a broad development space for rock wool sandwich panel manufacturing plants.

Industrial Construction

Industrial workshops are one of the main application scenarios of rock wool sandwich panels. Industrial workshops have high requirements for fire safety, thermal insulation and sound insulation. Rock wool sandwich panels have A-level non-combustible performance, which can effectively prevent the spread of fire and ensure the safety of the workshop. At the same time, their good thermal insulation performance can reduce the energy consumption of workshop heating and cooling, and their sound absorption performance can reduce the noise generated by equipment operation, improving the working environment of workers. In addition, rock wool sandwich panels are lightweight and easy to install, which can shorten the construction period of industrial workshops and reduce construction costs.

Logistics and Warehousing

In logistics and warehousing facilities (such as warehouses and cold storage centers), rock wool sandwich panels are widely used in walls and roofs. For ordinary warehouses, rock wool sandwich panels can provide good thermal insulation and moisture-proof performance, protecting the stored goods from the impact of the external environment. For cold storage centers, the low thermal conductivity of rock wool sandwich panels can effectively maintain the low-temperature environment inside the cold storage, reduce the energy consumption of refrigeration equipment and improve the efficiency of cold storage operation. In addition, the lightweight and high-strength characteristics of rock wool sandwich panels can reduce the load of the warehouse structure and increase the storage capacity of the warehouse.

Public Buildings and Prefabricated Buildings

Public buildings such as schools, hospitals and stadiums also have a large demand for rock wool sandwich panels. These buildings have high requirements for fire safety and comfort, and rock wool sandwich panels can meet these requirements well. For example, in hospitals, rock wool sandwich panels can provide a quiet and safe environment for patients and medical staff. In prefabricated buildings, rock wool sandwich panels are used as prefabricated components, which can be assembled quickly on-site, greatly shortening the construction period and adapting to the development trend of modern construction industrialization. In addition, rock wool sandwich panels can be customized in color and shape, which can meet the aesthetic requirements of public buildings.

Emergency Facilities

In emergency facilities such as mobile cabin hospitals and temporary resettlement houses, rock wool sandwich panels have become the preferred building material due to their fast installation speed and excellent performance. During the epidemic prevention and control period, mobile cabin hospitals built with rock wool sandwich panels can be put into use in a short time, providing a safe and comfortable medical environment for patients. In addition, in disaster-stricken areas, temporary resettlement houses built with rock wool sandwich panels can quickly solve the housing problem of the affected people, and their fire resistance and wind resistance can ensure the safety of the resettlement houses.

Future Development Trends of Rock Wool Sandwich Panel Manufacturing Plants

Faced with the changing market demand and technological progress, rock wool sandwich panel manufacturing plants are showing a development trend of intelligence, high performance and greenization.

Intelligent Production Upgrade

Intelligent production is an important development direction of rock wool sandwich panel manufacturing plants. With the application of technologies such as the Internet of Things, big data and artificial intelligence, manufacturing plants are realizing the intelligent transformation of the production line. For example, installing sensors on the production line to real-time monitor the operating status of the equipment and production parameters, and transmitting the data to the control center through the Internet of Things. The control center uses big data analysis technology to optimize the production process and predict potential equipment failures, improving production efficiency and product quality. In addition, robotic arms are used in the stacking and packaging links to reduce manual operations, improve work efficiency and reduce labor costs.

Development of High-Performance Products

With the continuous improvement of building standards, the market has higher and higher requirements for the performance of rock wool sandwich panels. Manufacturing plants are increasing investment in research and development to develop high-performance rock wool sandwich panels. For example, developing rock wool sandwich panels with higher fire resistance, lower thermal conductivity and stronger mechanical strength to meet the needs of special environments such as high-rise buildings and chemical plants. At the same time, developing functional rock wool sandwich panels such as waterproof, anti-corrosion and antibacterial to expand the application scope of the products. In addition, by optimizing the product structure and improving the production process, the lightweight and high-strength characteristics of the products are further enhanced, reducing the overall weight of the building and improving the seismic performance of the building.

Deepening of Green and Low-Carbon Development

Under the background of global carbon neutrality, green and low-carbon development has become an inevitable trend for rock wool sandwich panel manufacturing plants. Manufacturing plants will further strengthen environmental protection investment, adopt more advanced environmental protection technologies and equipment, and reduce carbon emissions and environmental pollution. For example, using renewable energy (such as solar energy and wind energy) to replace traditional fossil energy, reducing energy consumption and carbon emissions. At the same time, further improving the recycling rate of resources, realizing the closed-loop utilization of waste, and reducing the consumption of natural resources. In addition, manufacturing plants will also strengthen the research and development of green and environmentally friendly raw materials and adhesives, improving the environmental performance of products and promoting the sustainable development of the entire industry.

Market Expansion and International Cooperation

With the acceleration of global economic integration, rock wool sandwich panel manufacturing plants will actively expand the international market and carry out international cooperation. On the one hand, manufacturing plants will adjust product specifications and performance according to the needs of different countries and regions to adapt to the local building standards and market demand. On the other hand, manufacturing plants will strengthen cooperation with international raw material suppliers, technology research and development institutions and construction enterprises, introducing advanced technologies and management experience, and improving their international competitiveness. In addition, with the promotion of the "Belt and Road" initiative, manufacturing plants will have more opportunities to participate in international construction projects, expanding the market share of products and enhancing the influence of the brand.

Conclusion

Rock wool sandwich panel manufacturing plants are an important part of the construction material industry, and their development level is closely related to the safety, energy conservation and environmental protection of buildings. Through strict raw material selection, sophisticated production processes, comprehensive quality control systems and active environmental protection measures, manufacturing plants ensure the production of high-quality rock wool sandwich panels, providing strong support for the development of the construction industry. Faced with the future development opportunities and challenges, rock wool sandwich panel manufacturing plants will take intelligence, high performance and greenization as the development direction, continuously promote technological innovation and industrial upgrading, expand the market space and enhance international competitiveness. It is believed that with the continuous efforts of manufacturing plants, rock wool sandwich panels will play a more important role in the global construction industry, contributing to the realization of sustainable development goals.

« Rock Wool Sandwich Panel Manufacturing Plant » Update Date: 2026/1/9

URL: https://www.sinowamachine.com/tags/rock-wool-sandwich-panel-manufacturing-plant.html