In the realm of modern construction, the pursuit of energy efficiency, structural integrity, and construction speed has led to the widespread adoption of composite materials. Among these, Polyisocyanurate (PIR) sandwich panels have emerged as a preferred choice for roofing, wall cladding, and insulation applications, thanks to their exceptional thermal performance, fire resistance, and lightweight properties. At the heart of the mass production of these high-performance panels lies the PIR sandwich panel line—a sophisticated integration of automation, precision engineering, and material science.

Understanding PIR Sandwich Panels and the Role of Production Lines

Before delving into the intricacies of PIR sandwich panel lines, it is essential to grasp the unique characteristics of PIR sandwich panels that make them indispensable in modern construction. PIR panels feature a three-layer "sandwich" structure, consisting of two outer facings (typically galvanized steel, galvalume, or aluminum) and a central core of PIR foam. The PIR core is formed through a chemical reaction between polyols and isocyanates, resulting in a rigid foam with a closed-cell structure. This structure endows the panels with remarkable thermal insulation capabilities (thermal conductivity as low as 0.020 W/m·K), excellent fire resistance (often achieving B1 classification), and high structural strength despite their lightweight nature.

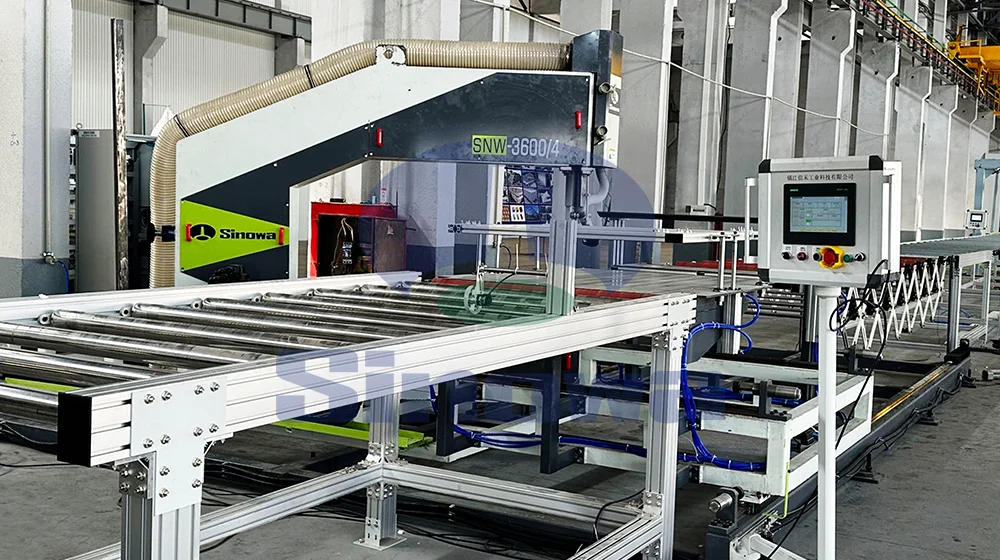

While the inherent properties of PIR panels drive their demand, it is the PIR sandwich panel line that enables the consistent, high-volume production of these panels to meet the rigorous standards of the construction industry. Unlike manual or semi-automatic production methods, modern PIR sandwich panel lines leverage continuous production processes, advanced automation, and precise control systems to ensure uniform quality, dimensional accuracy, and production efficiency. These lines are designed to handle the entire manufacturing cycle—from raw material preparation to finished product packaging—with minimal human intervention, reducing production time, minimizing waste, and ensuring product consistency.

Technological Fundamentals of PIR Sandwich Panel Lines

A PIR sandwich panel line is a complex assembly of interconnected modules, each designed to perform a specific function in the production process. The core technological principles that govern these lines revolve around precision material handling, controlled chemical reactions (for PIR foam formation), and uniform composite bonding. Key components of a typical PIR sandwich panel line include raw material handling systems, panel facing pretreatment modules, foam mixing and dispensing units, continuous lamination presses, cooling and cutting systems, and quality control stations. Each component is integrated into a centralized control system, allowing for real-time monitoring and adjustment of production parameters such as temperature, pressure, and speed.

One of the defining technological features of modern PIR sandwich panel lines is modular design. This design philosophy allows manufacturers to configure the line according to specific production requirements, such as panel size, thickness, and facing material. For instance, a single line can be adapted to produce roofing panels, wall cladding panels, or cold storage panels by adjusting the lamination pressure, foam formulation, and cutting dimensions. Modular design also facilitates easy maintenance, component replacement, and future upgrades, ensuring the line remains adaptable to evolving market needs and technological advancements.

Another critical technological aspect is the precision control of the PIR foam formation process. The chemical reaction that produces PIR foam is exothermic and requires precise control of temperature, mixing ratios, and dispensing rates to ensure the foam core achieves the desired density, cell structure, and mechanical properties. Modern PIR sandwich panel lines utilize high-pressure foaming machines with accurate metering pumps to deliver the polyol and isocyanate components in the correct proportions. The mixed components are then uniformly dispensed onto the lower facing material, where they undergo a controlled foaming process that fills the space between the two facings, creating a fully bonded composite panel.

The Operational Process of a PIR Sandwich Panel Line

The production process of PIR sandwich panels via a continuous line is a highly synchronized sequence of steps, each critical to the final quality of the product. Below is a detailed breakdown of the typical operational workflow:

Raw Material Preparation

The first stage involves the preparation of the three key raw materials: the upper and lower facings, and the PIR foam components. The facing materials, usually in the form of large coils (e.g., galvanized steel coils), are loaded onto uncoiling machines. These machines feature servo-driven correction systems to ensure the coils feed straight into the line, preventing misalignment that could affect panel quality. The coils are then fed through a series of flattening rollers to remove any curvature and ensure a smooth surface. Depending on the application, the facings may also undergo pre-pressing to form corrugated or trapezoidal profiles, which enhance their structural rigidity.

For the PIR foam core, the polyol and isocyanate components are stored in insulated tanks to maintain their optimal temperature (typically between 15°C and 25°C) for the chemical reaction. Additives such as flame retardants, blowing agents (often cyclopentane for environmental compatibility), and catalysts are also prepared and mixed with the main components according to precise formulations.

Facing Pretreatment (Optional)

In some production lines, the facings undergo additional pretreatment processes to improve the bonding strength between the facing material and the PIR core. This may include surface cleaning to remove dust, oil, or oxides, or the application of a primer that enhances adhesion. For metal facings, this step is particularly important as it ensures a durable bond that prevents delamination over time.

Foam Dispensing and Composite Formation

The prepped lower facing material is fed into the foam dispensing area, where the mixed PIR components are uniformly sprayed or poured onto its surface. The dispensing system is computer-controlled to ensure an even distribution of the foam mixture, which is critical for achieving a consistent core thickness and density. Immediately after dispensing, the upper facing material is fed over the foam mixture, forming a three-layer assembly (upper facing + foam mixture + lower facing) that moves into the lamination press.

Lamination and Curing

The three-layer assembly enters a continuous lamination press, which consists of a series of heated rollers or a belt press. The press applies a precise combination of temperature, pressure, and time to facilitate the foaming reaction and bond the three layers together. The temperature inside the press is typically maintained between 40°C and 60°C, which accelerates the curing of the PIR foam without compromising its properties. The pressure applied (usually between 0.5 and 2 MPa) ensures that the foam core adheres firmly to the facings and that the panel maintains a flat, uniform profile. This stage is critical—any deviation in temperature or pressure can result in poor bonding, uneven core density, or dimensional inaccuracies.

Cooling and Stabilization

After exiting the lamination press, the cured sandwich panel moves into a cooling zone. Here, the panel is cooled to ambient temperature using forced air or water-cooled rollers. Cooling is essential to stabilize the panel's dimensions and prevent warping or deformation as it cools naturally. The cooling process also ensures that the PIR foam core completes its curing reaction, achieving its full mechanical and thermal properties.

Cutting and Trimming

Once cooled, the continuous panel is fed into a computerized cutting system, which trims the panel to the desired length (customizable up to 18 meters or more) using high-precision saws. The cutting system is synchronized with the line speed to ensure clean, accurate cuts without damaging the panel edges. Additional trimming may be performed to smooth the edges, and optional processes such as slotting (for easy installation and lap) or punching (for mounting accessories) can be integrated at this stage.

Quality Control and Packaging

The finished panels undergo a rigorous quality control inspection to ensure they meet the required standards. Inspectors check for dimensional accuracy, surface defects (such as scratches or dents), bonding strength (via random sampling and testing), and core density. Panels that fail to meet the standards are rejected or reworked. Qualified panels are then packaged using protective materials such as corner guards and stretch film to prevent damage during transportation and storage. The packaged panels are typically stored vertically to save space and maintain their structural integrity before being shipped to construction sites.

Key Advantages of Modern PIR Sandwich Panel Lines

Modern PIR sandwich panel lines offer a multitude of advantages over traditional production methods, making them a cornerstone of efficient and sustainable panel manufacturing. These advantages can be categorized into four main areas: production efficiency, product quality, cost-effectiveness, and environmental sustainability.

Enhanced Production Efficiency

One of the most significant benefits of PIR sandwich panel lines is their high production speed and continuous operation. Modern lines can achieve production speeds of up to 25 meters per minute, enabling the manufacture of thousands of square meters of panels per day. This continuous production capability eliminates the downtime associated with batch processing, significantly increasing overall output. Additionally, the high degree of automation reduces the need for manual labor, minimizing human error and further boosting efficiency. The centralized control system allows operators to monitor and adjust production parameters in real time, ensuring optimal performance and maximizing throughput.Consistent Product Quality

Consistency is a critical factor in construction materials, and PIR sandwich panel lines excel in delivering uniform product quality. The precision engineering of the line components—from the foam dispensing system to the lamination press—ensures that every panel has the same core density, thickness, and bonding strength. The automated control system maintains strict control over temperature, pressure, and mixing ratios, eliminating the variability introduced by manual operations. This consistency ensures that the panels meet the rigorous performance standards required for construction applications, such as thermal insulation, fire resistance, and structural load-bearing capacity.Cost-Effectiveness

While the initial investment in a PIR sandwich panel line may be significant, the long-term cost savings are substantial. The high production efficiency reduces the unit cost of each panel, making PIR panels more competitive with traditional building materials such as concrete or brick. The automation of the production process reduces labor costs, and the precise material handling minimizes waste—both of which contribute to lower production costs. Additionally, the modular design of modern lines reduces maintenance costs and allows for easy upgrades, extending the lifespan of the equipment. The lightweight nature of PIR panels, produced efficiently by these lines, also reduces transportation and installation costs, further enhancing their cost-effectiveness in construction projects.Environmental Sustainability

In an era of increasing focus on sustainability, PIR sandwich panel lines are designed to minimize their environmental impact. The closed-cell structure of PIR foam makes it highly energy-efficient, reducing the carbon footprint of buildings by lowering heating and cooling energy consumption. Modern lines use environmentally friendly blowing agents such as cyclopentane, which have zero ozone depletion potential (ODP) and low global warming potential (GWP), replacing harmful alternatives like CFCs or HCFCs. Additionally, the efficient material usage and waste reduction in production processes minimize the amount of raw material consumed and waste generated. Some advanced lines also incorporate energy recovery systems, which capture and reuse the heat generated during the PIR foam curing process, further reducing energy consumption.

Diverse Applications of PIR Panels Produced by Sandwich Panel Lines

The versatility of PIR panels, enabled by the flexible production capabilities of PIR sandwich panel lines, makes them suitable for a wide range of construction applications across various sectors. Below are some of the key application areas:

Industrial and Manufacturing Facilities

Industrial warehouses, manufacturing plants, and logistics centers are the largest consumers of PIR sandwich panels. These facilities require large-scale roofing and wall cladding solutions that offer excellent thermal insulation, durability, and quick installation. PIR panels produced by continuous lines are ideal for these applications, as they can be manufactured in long lengths (up to 18 meters) to cover large areas with minimal joints, reducing installation time and improving water resistance. The lightweight nature of the panels also reduces the structural load on the building's framework, lowering construction costs.Cold Storage and Refrigeration

Cold storage facilities, refrigerated warehouses, and food processing plants require insulation materials with exceptional thermal performance to maintain low temperatures efficiently. PIR panels are the preferred choice for these applications due to their low thermal conductivity and closed-cell structure, which prevents moisture absorption and maintains insulation performance over time. PIR sandwich panel lines can be configured to produce panels with thicker cores (up to 200 mm) to meet the high insulation requirements of cold storage facilities. The fire resistance of PIR panels also makes them a safe choice for food processing environments, where fire safety is a critical concern.Commercial and Public Buildings

Commercial buildings such as shopping malls, office complexes, and exhibition centers, as well as public buildings like schools, hospitals, and sports stadiums, benefit from the aesthetic versatility and performance of PIR panels. PIR sandwich panel lines can produce panels with a variety of facing materials, including pre-painted steel, aluminum, and fiber cement, allowing for customization to match the architectural design of the building. The quick installation of PIR panels reduces construction time, minimizing disruption to surrounding areas—a key advantage for urban construction projects. Additionally, the energy efficiency of PIR panels helps reduce the operational costs of commercial and public buildings, which often have high energy demands.Residential and Modular Construction

The growing trend toward modular and prefabricated housing has increased the demand for PIR panels. PIR sandwich panel lines can produce panels that are pre-cut to precise dimensions, making them ideal for modular construction, where components are manufactured in a factory and assembled on-site. These panels offer excellent thermal insulation, reducing energy costs for homeowners, and their lightweight nature simplifies transportation and assembly. PIR panels are also used for interior partitioning in residential buildings, providing sound insulation and fire protection while saving space compared to traditional brick walls.Specialized Applications

Beyond mainstream construction, PIR panels produced by advanced sandwich panel lines are used in specialized applications such as cleanrooms (in pharmaceutical and electronic manufacturing), agricultural buildings (greenhouses and livestock shelters), and transportation infrastructure (railway stations and airports). In cleanrooms, PIR panels with smooth, easy-to-clean facings (such as stainless steel or PVC) are used to maintain a sterile environment. In agricultural applications, the thermal insulation of PIR panels helps regulate temperature and humidity, improving crop yields and livestock health.

Future Trends in PIR Sandwich Panel Line Technology

As the construction industry continues to evolve toward greater sustainability, automation, and digitalization, PIR sandwich panel lines are poised to undergo significant technological advancements. Below are some of the key trends shaping the future of these production lines:

Increased Automation and Digitalization

The future of PIR sandwich panel lines lies in full automation and digitalization. Advances in artificial intelligence (AI) and the Internet of Things (IoT) will enable real-time monitoring and predictive maintenance of production lines. Sensors embedded in key components will collect data on temperature, pressure, vibration, and material flow, allowing AI algorithms to detect potential issues before they cause downtime. Digital twin technology—creating a virtual replica of the production line—will enable operators to simulate production processes, optimize parameters, and test new configurations without disrupting actual production. These digital advancements will further improve production efficiency, reduce maintenance costs, and enhance product quality.Focus on Sustainable Materials and Processes

Sustainability will remain a key driver of innovation in PIR sandwich panel lines. Manufacturers will continue to develop and adopt environmentally friendly foam formulations, using bio-based polyols derived from renewable resources (such as vegetable oils) instead of petroleum-based materials. Additionally, lines will be designed to further reduce energy consumption, incorporating more efficient heating and cooling systems, and utilizing renewable energy sources such as solar or wind power. Waste reduction will also be a priority, with advanced recycling systems integrated into production lines to reuse scrap materials and reduce landfill waste.Enhanced Flexibility and Customization

The demand for customized PIR panels will drive the development of more flexible production lines. Future lines will be able to switch between different panel configurations (size, thickness, facing material, core density) more quickly, with minimal downtime. This flexibility will enable manufacturers to meet the specific requirements of individual projects, from small-scale residential renovations to large-scale industrial developments. Advanced cutting and shaping technologies, such as laser cutting, will also allow for more complex panel designs, expanding the architectural possibilities of PIR panels.Integration with Smart Construction Systems

As the construction industry becomes more digitalized, PIR sandwich panel lines will be integrated with smart construction systems. Panels produced by these lines may include embedded sensors that monitor temperature, humidity, and structural integrity once installed in a building. The production data from the line (such as panel dimensions, material specifications, and quality control results) can be linked to building information modeling (BIM) systems, enabling seamless integration of PIR panels into the overall building design. This integration will improve the efficiency of the entire construction process, from design to installation and maintenance.

Conclusion

The PIR sandwich panel line has evolved from a simple production tool to a sophisticated, technology-driven system that plays a vital role in modern construction. By enabling the efficient, consistent production of high-performance PIR sandwich panels, these lines have revolutionized the way buildings are designed and constructed, offering a perfect balance of energy efficiency, structural strength, and construction speed. From industrial warehouses to residential homes, from cold storage facilities to commercial complexes, PIR panels produced by these lines have become an integral part of diverse construction projects worldwide.

As technology continues to advance, PIR sandwich panel lines will become even more efficient, sustainable, and flexible, further driving the adoption of PIR panels in the construction industry. The integration of automation, digitalization, and sustainable practices will not only improve production processes but also contribute to the development of greener, more resilient buildings. In a world where sustainability and efficiency are paramount, the PIR sandwich panel line stands as a testament to the power of technological innovation in shaping a better future for construction.

« PIR Sandwich Panel Line » Update Date: 2026/1/12

URL: https://www.sinowamachine.com/tags/pir-sandwich-panel-line.html