Polyurethane sandwich panels have emerged as a versatile and high-performance composite material widely adopted in construction, industrial, and cold chain sectors, owing to their integrated advantages of thermal insulation, structural stability, and easy installation. The manufacturing line that produces these panels is a sophisticated integration of mechanical systems, chemical processing units, and automated control technologies, designed to ensure consistent quality, efficient production, and adaptability to diverse product requirements. Understanding the structure of the manufacturing line, the performance characteristics of the panels it produces, the various types of panels available, and their extensive applications is essential for appreciating the value of this technology in modern industrial and construction practices.

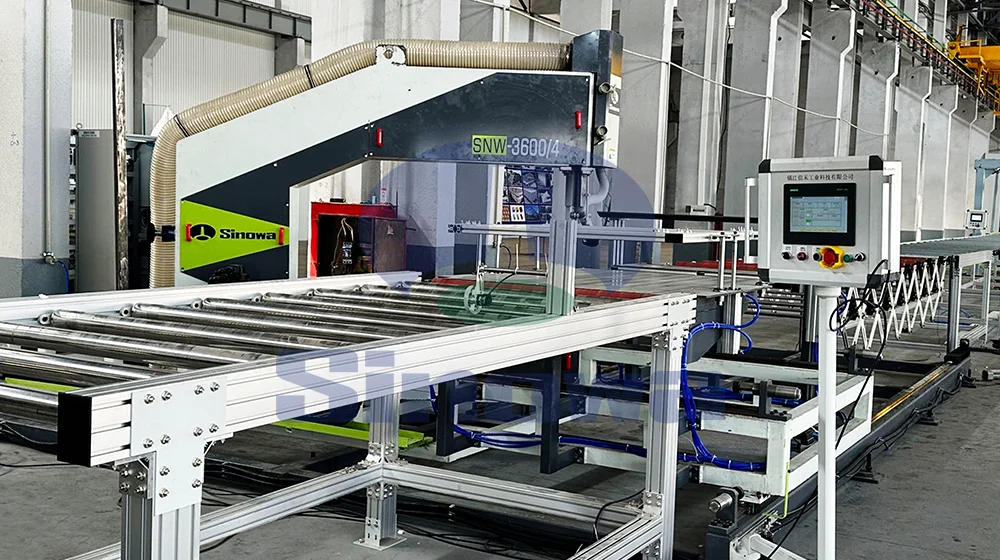

The structure of a polyurethane sandwich panel manufacturing line is composed of several core functional modules that work in tandem to transform raw materials into finished panels through a continuous or semi-continuous process. The primary components include uncoiling systems, roll forming units, high-pressure foaming systems, lamination and curing conveyors, cutting systems, and post-processing equipment, all coordinated by a central control system. The uncoiling system serves as the starting point, responsible for feeding surface materials—typically metal coils such as pre-coated steel, aluminum, or stainless steel—into the production line. These surface materials provide structural rigidity, corrosion resistance, and aesthetic appeal to the final panels. The uncoilers are equipped with tension control mechanisms to ensure the flatness of the metal sheets and prevent wrinkles or deformations during subsequent processing. Some advanced lines also integrate levelers and surface treatment units, such as corona treatment or protective film application, to enhance the adhesion between the surface materials and the polyurethane core, as well as to protect the surface from scratches during production.

Following the uncoiling process, the metal sheets are fed into roll forming units. These units consist of a series of tandem rolling stands with precision-engineered rollers that progressively bend and shape the metal sheets into the desired profiles. The profiles can vary based on the intended use of the panels—for example, trapezoidal or corrugated profiles for roof panels, and flat or grooved profiles for wall panels. The roll forming process is highly customizable, allowing for adjustments in width, thickness, and profile design to meet specific project requirements. For panels with hidden fasteners, the roll forming units also shape the edges to create interlocking joints, ensuring a seamless and aesthetically pleasing finish. After forming, the upper and lower surface sheets are guided into a parallel configuration, creating a gap between them where the polyurethane core will be injected.

The high-pressure foaming system is the heart of the manufacturing line, responsible for producing and distributing the polyurethane foam core. This system consists of metering pumps, mixing heads, and foam distribution units. The polyurethane foam is formed by reacting two main components—polyol and isocyanate—along with additives such as flame retardants, blowing agents, and catalysts. The metering pumps accurately dispense the components in a predetermined ratio, ensuring consistent foam density and performance. The components are then mixed under high pressure in the mixing head, which ensures thorough homogenization. The blowing agent causes the mixture to expand, filling the gap between the upper and lower surface sheets. The foam distribution units are designed to evenly spread the foam mixture across the entire width of the panels, preventing uneven core thickness or voids that could compromise performance. Some systems also incorporate nucleators to control the cell structure of the foam, enhancing its thermal insulation and mechanical properties.

Once the foam is injected, the sandwich structure moves into a lamination and curing conveyor system, often referred to as a double belt press. This system consists of two parallel, continuous belts that apply uniform pressure and temperature to the panel as it moves through the line. The pressure ensures that the foam adheres firmly to the surface sheets and maintains a consistent thickness, while the controlled temperature accelerates the curing process of the polyurethane foam. The belts are typically made of heat-resistant materials and are independently heated to create optimal curing conditions. The curing time varies depending on the foam formulation and panel thickness, but the continuous nature of the line allows for high production speeds. After curing, the foam transforms into a rigid, closed-cell structure that bonds tightly to the surface materials, forming a cohesive composite panel.

The cutting system is the next stage in the production process, responsible for trimming the continuous panel into fixed lengths according to customer specifications. Most modern lines use flying saws or band saws equipped with precision cutting mechanisms that can cut the panels while they are still moving, ensuring high efficiency and minimal production downtime. The cutting systems are integrated with sensors and position encoders to maintain accurate length tolerance, typically within a few millimeters. After cutting, the panels may undergo post-processing steps such as edge trimming, deburring, or surface cleaning to remove any excess foam or debris. Some lines also include stacking and wrapping units to automate the packaging process, protecting the panels during transportation and storage.

The central control system, usually based on programmable logic controllers (PLC), oversees the entire production process, integrating feedback from sensors throughout the line to adjust parameters such as speed, temperature, pressure, and foam ratio in real time. This automation ensures consistent product quality, reduces human error, and allows for quick adjustments when switching between different panel specifications. Advanced control systems may also include data logging and remote monitoring capabilities, enabling operators to track production efficiency, identify potential issues, and optimize the process for better performance.

The performance of polyurethane sandwich panels is a direct result of the manufacturing process and the properties of their components, combining the structural strength of the surface materials with the thermal and mechanical characteristics of the polyurethane core. One of the most notable performance attributes is thermal insulation efficiency. Polyurethane foam has an extremely low thermal conductivity, typically ranging from 0.022 to 0.028 W/(m·K), which is significantly lower than traditional insulation materials such as expanded polystyrene (EPS) or mineral wool. This low thermal conductivity is attributed to the closed-cell structure of the foam, which traps air within the cells and minimizes heat transfer through conduction and convection. As a result, polyurethane sandwich panels can effectively maintain temperature differentials between the interior and exterior of a structure, reducing energy consumption for heating and cooling. This property is particularly valuable in cold storage facilities, food processing plants, and industrial buildings where precise temperature control is critical.

In addition to thermal insulation, polyurethane sandwich panels exhibit excellent structural strength and rigidity. The combination of rigid foam core and high-strength surface materials creates a composite structure that can withstand significant compressive, tensile, and bending forces. The surface materials, especially metal sheets, provide resistance to impact and wear, while the foam core distributes loads evenly across the panel. This structural integrity allows the panels to be used as self-supporting elements in walls and roofs, eliminating the need for additional structural framing in some applications. The panels also have a high strength-to-weight ratio, as they are lightweight compared to traditional building materials such as concrete or brick, yet retain sufficient strength to meet building requirements. This lightweight nature simplifies transportation and installation, reducing labor and logistics costs.

Moisture resistance is another key performance characteristic of polyurethane sandwich panels. The closed-cell structure of the foam core prevents water vapor penetration, reducing the risk of moisture accumulation, mold growth, and structural degradation. This makes the panels suitable for use in humid environments such as coastal areas, food processing facilities, and cold storage, where moisture control is essential. The surface materials, particularly when coated with anti-corrosion layers, further enhance the panel's resistance to moisture and chemical exposure, extending its service life.

Sound insulation performance is also a notable advantage of polyurethane sandwich panels. The foam core effectively absorbs sound waves, reducing noise transmission between spaces. This property is beneficial in industrial settings, where machinery noise can be excessive, as well as in commercial and residential buildings where acoustic comfort is important. The combination of sound and thermal insulation makes the panels a versatile solution for multi-purpose structures.

Fire performance is a critical consideration for any building material, and polyurethane sandwich panels can be formulated to meet specific fire safety requirements. While polyurethane foam is inherently flammable, the addition of flame retardants during the foaming process can reduce its combustibility, limiting flame spread and smoke production. The closed-cell structure also helps to prevent the foam from crumbling when exposed to fire, maintaining structural integrity for a longer period. The performance varies depending on the formulation and thickness of the foam, as well as the type of surface materials used. Metal-faced panels, for example, can provide additional fire resistance by acting as a barrier between the foam core and the fire source.

Durability is another important performance attribute, with polyurethane sandwich panels typically having a service life of 20 to 30 years when properly installed and maintained. The surface materials are resistant to corrosion, UV radiation, and weathering, while the foam core is stable and does not degrade significantly over time. This long service life reduces the need for frequent replacement, making the panels a cost-effective solution in the long term.

Polyurethane sandwich panels can be classified into various types based on their structure, surface materials, foam formulation, and intended application. One common classification is based on the type of surface material used. Metal-faced panels are the most widely used, with pre-coated steel being the most common due to its cost-effectiveness, corrosion resistance, and aesthetic versatility. Aluminum-faced panels are lighter and offer better corrosion resistance in harsh environments, making them suitable for coastal areas or chemical plants. Stainless steel-faced panels are used in applications requiring high hygiene standards, such as pharmaceutical facilities and food processing plants, due to their easy-to-clean surface and resistance to chemical contamination.

Another classification is based on the panel's intended use, resulting in wall panels, roof panels, cold storage panels, and specialized panels such as clean room panels or sound insulation panels. Wall panels are designed for vertical installation and can be further categorized into hidden joint and open-screw joint panels. Hidden joint panels have interlocking edges that conceal fasteners, providing a seamless and aesthetically pleasing finish, while open-screw joint panels use visible fasteners for easier installation, making them suitable for industrial buildings where appearance is less critical. Roof panels are typically designed with trapezoidal or corrugated profiles to facilitate water drainage and provide additional structural strength against snow and wind loads. They may also include features such as hidden fasteners to prevent water penetration.

Cold storage panels are a specialized type of polyurethane sandwich panel designed for low-temperature environments. These panels have a higher foam density and thicker core to enhance thermal insulation, typically ranging from 100 to 250 mm in thickness. The foam formulation is optimized for performance at sub-zero temperatures, maintaining flexibility and insulation efficiency even at -40°C or lower. Cold storage panels may also have seamless joints and airtight seals to prevent temperature fluctuations and energy loss. Some are designed with stainless steel surfaces for easy cleaning and hygiene compliance in food and pharmaceutical storage.

Based on the foam formulation, polyurethane sandwich panels can be divided into polyurethane (PU) and polyisocyanurate (PIR) panels. PIR panels are a variant of polyurethane, with enhanced thermal stability and fire resistance. PIR foam has a higher cross-link density, resulting in better thermal performance at high temperatures and improved fire resistance compared to traditional PU foam. PIR panels are typically used in applications requiring higher fire safety standards or where the panels will be exposed to elevated temperatures, such as industrial furnaces or commercial buildings with strict fire codes.

Specialized panels include clean room panels, which are designed for environments requiring controlled cleanliness, such as electronics manufacturing facilities and pharmaceutical labs. These panels have smooth, non-porous surfaces that resist dust accumulation and are easy to sanitize. Sound insulation panels have a modified foam core with enhanced sound absorption properties, used in concert halls, recording studios, and industrial noise control applications. Decorative panels are another type, featuring embossed or printed surface materials to mimic natural materials such as wood, stone, or brick, making them suitable for interior and exterior decorative applications.

The applications of polyurethane sandwich panels are diverse, spanning the construction, industrial, cold chain, transportation, and commercial sectors, driven by their versatile performance characteristics. In the construction industry, they are widely used for the walls and roofs of industrial buildings, warehouses, exhibition halls, gymnasiums, and prefabricated houses. Industrial buildings benefit from the panels' thermal and sound insulation properties, as well as their quick installation, which reduces construction time and minimizes downtime for production facilities. Warehouses and large-span structures take advantage of the panels' lightweight design and structural strength, allowing for larger open spaces without the need for excessive supporting columns. Prefabricated houses use the panels due to their ease of transportation and assembly, enabling rapid construction of residential and commercial units.

The cold chain industry is one of the largest consumers of polyurethane sandwich panels, where they are used in the construction of cold storage facilities, freezers, refrigerated trucks, and containerized cold boxes. Cold storage facilities rely on the panels' superior thermal insulation to maintain consistent low temperatures, reducing energy consumption and ensuring the quality of perishable goods such as food, pharmaceuticals, and biological samples. Refrigerated trucks and containers use lightweight panels to maximize payload capacity while maintaining temperature stability during transportation. The panels' moisture resistance is also critical in these applications, preventing frost buildup and maintaining insulation efficiency over time.

In the industrial sector, polyurethane sandwich panels are used for sound insulation walls, clean room enclosures, and equipment housings. Sound insulation walls are installed around factories and machinery to reduce noise pollution, improving working conditions for employees and minimizing impact on surrounding communities. Clean rooms in electronics and pharmaceutical plants use the panels to create controlled environments with minimal dust and contamination, thanks to their smooth, easy-to-clean surfaces and airtight joints. Equipment housings benefit from the panels' structural strength and thermal insulation, protecting sensitive machinery from environmental factors and reducing noise emissions.

The transportation sector utilizes polyurethane sandwich panels in the interior and exterior of recreational vehicles (RVs), trailers, and ship cabins. RVs and trailers use lightweight panels to maximize fuel efficiency and interior space, while providing thermal insulation for comfort. Ship cabins benefit from the panels' moisture resistance and sound insulation, creating a comfortable living environment for crew members. The panels are also used in the construction of modular buildings for temporary or permanent use in remote areas, such as construction sites or disaster relief zones, due to their quick installation and durability.

Commercial buildings, such as shopping malls, office buildings, and hotels, use polyurethane sandwich panels for their aesthetic versatility and performance. Decorative panels can be used for interior walls and ceilings, creating visually appealing spaces with minimal maintenance. The panels' thermal insulation also helps reduce energy costs for heating and cooling, making commercial buildings more energy-efficient. Hotels and hospitals use the panels for sound insulation between rooms, enhancing guest and patient comfort.

Agricultural applications are another growing area for polyurethane sandwich panels, used in the construction of greenhouses, livestock barns, and agricultural storage facilities. Greenhouses benefit from the panels' thermal insulation to maintain optimal growing temperatures, extending the growing season and improving crop yields. Livestock barns use the panels to provide a comfortable environment for animals, regulating temperature and reducing noise. Agricultural storage facilities use the panels to protect crops and equipment from the elements, with moisture resistance preventing mold and spoilage.

The versatility of polyurethane sandwich panels is further enhanced by their customizability, allowing for adjustments in thickness, size, surface material, and foam formulation to meet the specific needs of different applications. This adaptability, combined with their superior performance and efficient manufacturing process, makes them a preferred choice for a wide range of industries. As demand for energy-efficient, durable, and sustainable building materials continues to grow, the polyurethane sandwich panel manufacturing line and its products are expected to play an increasingly important role in modern construction and industrial practices. The ongoing advancement in manufacturing technology, such as improved automation, foam formulations, and surface treatments, will further enhance the performance and applications of these panels, solidifying their position as a key component in the global building materials market.

In summary, the polyurethane sandwich panel manufacturing line is a complex integration of mechanical and chemical processes that produce high-performance composite panels with a unique combination of thermal insulation, structural strength, and versatility. The line's modular structure allows for customization and high production efficiency, while the panels' diverse types and applications cater to the needs of multiple industries. From cold storage facilities to commercial buildings, from industrial plants to agricultural structures, polyurethane sandwich panels continue to demonstrate their value as a reliable, efficient, and cost-effective building material, driven by ongoing innovations in manufacturing technology and material science.

« Polyurethane Sandwich Panel Manufacturing Line » Update Date: 2026/1/24

URL: https://www.sinowamachine.com/tags/polyurethane-sandwich-panel-manufacturing-line.html